The Idea: Launching a Personalized Bottle Store

Viström, a Swedish digital development agency, was working on a new eCommerce project for their client, Carpmans. Known for their work in packaging, printing, and filling chemical-technical products, Carpmans decided to branch out with a new initiative: an online store where customers could order personalized water bottles.

This led to the launch of DesignDirekt, a dedicated storefront focused on offering custom-printed bottles for teams, businesses, and individual customers.

To make this idea a reality, Viström began looking for a web-to-print solution that could be integrated into the online storefront and support the personalization process. The platform needed to work with multi-layered design templates, provide a 3D product preview, and generate print-ready files with variable data printing (VDP) capabilities.

Customer’s Canvas stood out as the ideal fit to power this new digital product customization journey.

The Challenge: Powering a Flexible Web-to-Print Workflow Through API Integration

In this project, the integration of Customer’s Canvas into the website was handled by the development team at Viström. To support this approach, the platform needed to offer the flexibility and developer tools required for building a fully customized personalization experience.

Customer’s Canvas provided full access to its APIs and SDK, allowing Viström to seamlessly connect the editor with the client’s eCommerce infrastructure and implement the entire workflow on their side.

To implement this integration, Viström used Customer’s Canvas to:

- Manage assets by uploading, organizing, and applying user images and design elements;

- Embed the editor with support for layered templates and variable fields;

- Generate 3D previews to let users visualize their designs on the actual product;

- Render print-ready PDFs with high resolution and support for variable data printing (VDP).

Customer's Canvas has provided excellent support that has helped us move forward, as a project like this has presented many challenges for everyone involved.

The Solution: Implementing a VDP-Driven Customization Workflow

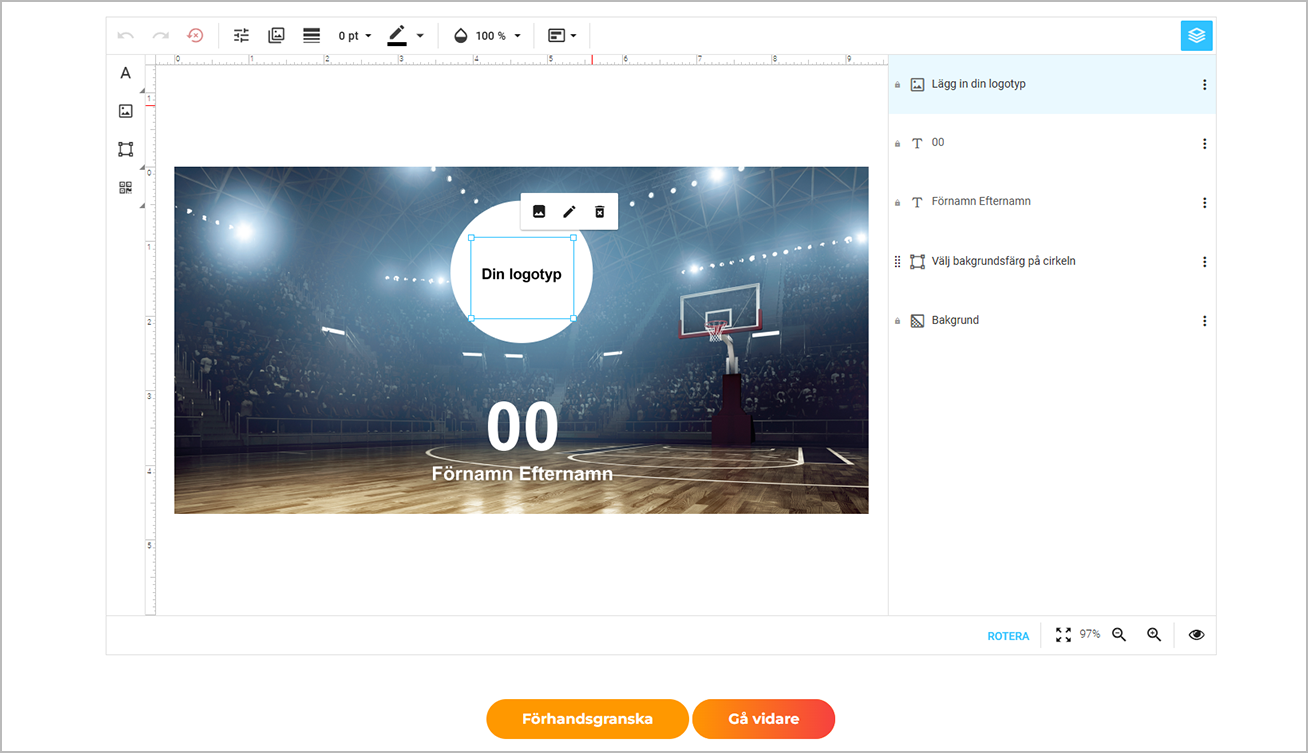

Using the Customer’s Canvas API and SDK, the Viström team implemented a seamless and intuitive personalization workflow for the DesignDirekt storefront. The process begins with product selection: users choose the bottle type and color, and then proceed to browse a gallery of predefined design templates.

Once a template is selected, the customer enters the Customer’s Canvas editor. Here, they personalize their design by editing text, uploading logos, and adding other images. The editor supports layered templates and provides a flexible interface that guides users through the customization process.

After completing the design, the platform generates a realistic 3D preview of the bottle. This helps customers preview their personalized artwork on the actual product, boosting confidence before ordering.

In the final step, users enter individual personalization details—such as a player’s name and number—and specify the number of bottles to be produced with each variation. This stage fully utilizes the variable data printing (VDP) capabilities of Customer’s Canvas, enabling batch orders where each item includes unique data, while maintaining an efficient and unified workflow.

Once the order is submitted, the Customer’s Canvas rendering engine automatically generates print-ready PDF files with all variable elements applied. These high-resolution files are production-ready, ensuring a smooth handoff to manufacturing with no loss in quality or accuracy.

The Results: Personalized Bottles, Automated Orders, Better Business

Integrating Customer’s Canvas into the DesignDirekt store turned out to be a perfect example of how technology and expertise can come together to create something both user-friendly and efficient. By utilizing the Customer’s Canvas API and SDK, the Viström team built a unique bottle customization process that’s easy to use while providing an excellent experience for customers. Shoppers can quickly choose a template, add text and images, and then see how their design will look on the bottle with a 3D preview.

This seamless workflow doesn’t just stop at design. The system also generates print-ready files with support for variable data printing (VDP), simplifying the production process. As a result, Carpmans was able to offer high-quality personalized bottles while benefiting from a streamlined, scalable process that works smoothly for both individual and bulk orders.

Download PDF