Today, most print shops still accept orders that require finishing the old-fashioned way. This means a long process of reconciliation, complete with a long chain of emails to confirm the final design and eventually billing the client. Very few companies decide to develop their own solutions for processing such orders online. This is mainly because it takes a lot of time, money, and an in-house team of technical specialists, which not every printing company can afford. Therefore, most orders for such unique products are still processed the same way they were 10 or 20 years ago.

The main difficulty of getting such orders online is that finishing is performed after printing with different equipment and technical requirements in mind. So, ready-to-print files must contain information for both the printing and finishing equipment. At the same time, both the printing and finishing elements of the design need to be on a single canvas to give customers an idea of how their product will look.

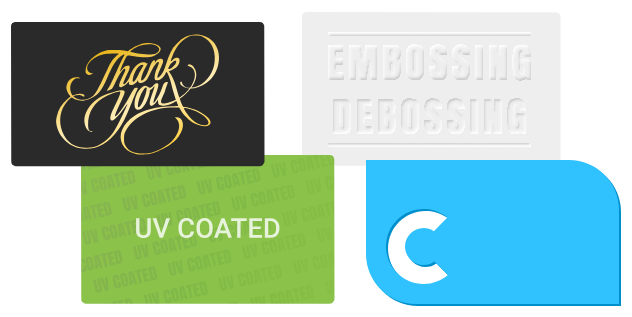

Our engineers at Customer’s Canvas by Aurigma have added the ability to work with spot colors in the latest version of our online W2P editor. The term “spot color” initially referred to color generated by an ink used in single-run printing as opposed to creating a color by printing a series of dots of different colors. This term came from offset printing, and with the development of new technologies, began to denote not only printing with specially prepared ink, but also the application of effects requiring the manufacture of special tools, such as a stamp for foil or embossing.

This new functionality allows your customers to create a design for a printed product with the inclusion of finishing elements. Users can create items designed for post-processing just as the case with regular print design and can view the final result in real time. The user can convert text, vector elements, or any raster image – such as a logo or photo – to a spot channel, and those elements will be created during the finishing process. The spot channel is preconfigured to meet the technical requirements of the equipment for parameters like line thickness, resolution, and others.

After a client finishes the design, they can review the result, complete their order, and send the job to print. A template prepared in the WYSIWYG editor is then exported, preserving the spot channel as a separate layer. After that, the product is printed and postpress techniques are applied.

Implementing support for spot channels can also be used for other applications. For example, spot colors can be used to mark cutting, creasing, and folding lines for packaging products, brochures, postcards, or stickers. Not to mention, the initial use of spot colors for printing the elements for which a precise color is required, e.g. to match branding guidelines. In addition, several spot channel layers can be used to create complex designs with several stages of postpress processing, such as combining embossing with UV-coating.

Integrating a web-to-print editor with spot color support in your online storefront allows your printing company to provide its customers with additional opportunities to create unique designs using post-printing processing (foil, embossing, UV-coating) without complicating the order workflow. The process of creating a design with post-print effects is simple and intuitive. For a printing company, this means gaining an additional advantage over competitors, as well as increasing the profit margin of an order without spending additional resources on order processing.

Flexible options for setting up spot channels can enable you to adapt the parameters of print-ready files to your equipment and internal printing processes. You can configure the way spot channels are exported from the editor: as overprint in print-ready files, by exporting it as a separate page, or by exporting it as a compatible PDF file.

Contact our representatives to discuss how support for spot channels and the other functionalities of our online editor that can help your printing company to increase its efficiency and open up new opportunities for development.

How to find us at the exhibition:

Our team will be waiting for you at booth #239, where convenient places will be arranged for demo testing. Our representatives will be more than happy to address any questions or concerns that you may have about our products and how they fit in with your unique business requirements.

You can schedule a meeting with us at a convenient time for you to showcase new Customer's Canvas features and answer any questions.

About Print 18

PRINT is the annual conference and exhibition event that hosts the largest gathering of printing services providers in North America, representing attendees from 86 countries. In 2017, more than 22,000 visitors came to Chicago, including nearly 16,000 buyers from 8,565 companies.